Are you experiencing performance issues with your diesel mechanic car? Understanding the common problems and adhering to a consistent maintenance schedule is crucial for keeping your diesel engine running smoothly and efficiently. This comprehensive guide explores the typical issues encountered by diesel vehicles and provides actionable maintenance tips to prolong their lifespan and optimize their performance.

All About Diesel Engines: Common Issues and Maintenance Tips

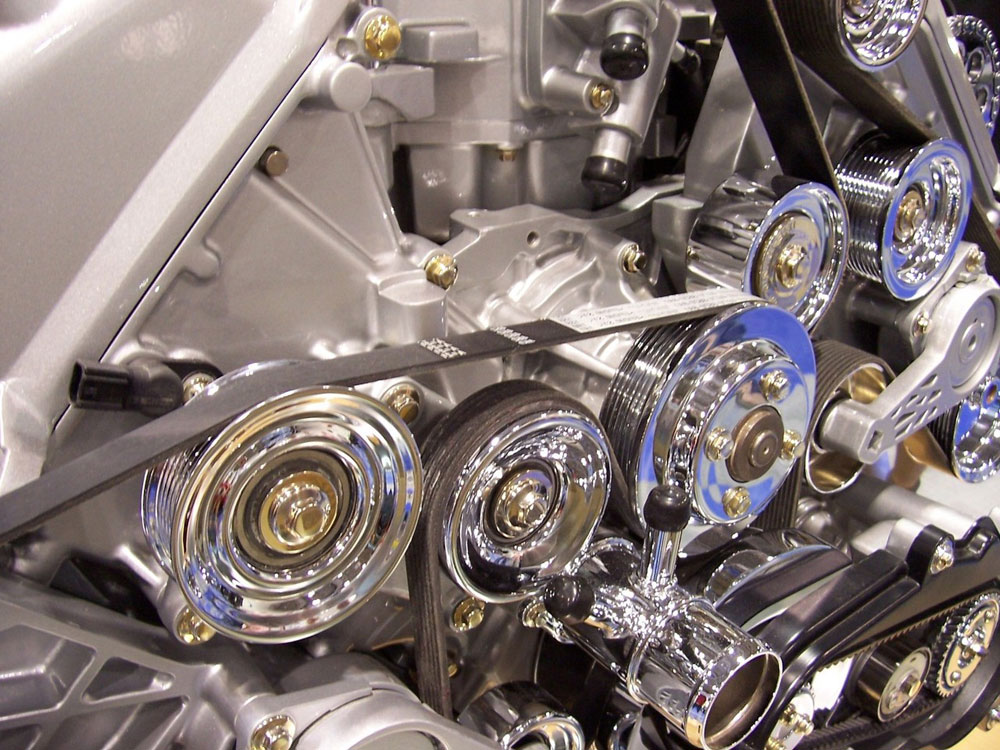

Diesel engines are renowned for their power, fuel efficiency, and durability, making them a popular choice for trucks, SUVs, and even passenger cars. However, like any complex machine, diesel engines are susceptible to specific problems if not properly maintained. This guide will help you understand the common issues associated with diesel vehicles and equip you with the knowledge to keep your diesel car in top condition. Diesel engines' significance lies in their superior torque output compared to gasoline engines, making them ideal for heavy-duty applications. Historically, diesel engines have been primarily used in commercial vehicles, but their presence in passenger cars has steadily increased, driven by advancements in technology and stricter fuel economy standards. A key differentiating feature of diesel engines is their reliance on compression ignition, where air is compressed to a high temperature, igniting the injected fuel, unlike gasoline engines that use spark plugs. Diesel engines, when well-maintained, provide exceptional longevity, often exceeding 200,000 miles or more.

Benefits of Proper Diesel Engine Maintenance for Users

Regular maintenance of your diesel engine provides several benefits, most notably enhanced performance and increased fuel efficiency. Neglecting maintenance can lead to decreased power, rough idling, and even engine failure, resulting in costly repairs. Proper maintenance helps to maintain the peak torque output, maximizing the vehicle's towing capacity and overall performance. Real-world examples showcase the benefits: a well-maintained diesel truck can consistently haul heavy loads without strain, while a neglected diesel car might struggle with even moderate inclines. Compared to gasoline engines, diesels, with proper care, can offer significantly longer lifespans. Studies have shown that diesel engines can outlast gasoline engines by up to 30%, given consistent and appropriate maintenance.

How to Maintain Your Diesel Engine: Step-by-Step

1. Regular Oil Changes

Changing your engine oil regularly is paramount. Diesel engines produce more soot and contaminants than gasoline engines, which quickly degrade the oil's lubricating properties.

Best Practices: Follow the manufacturer's recommended oil change interval, typically between 5,000 and 7,500 miles. Use a high-quality oil specifically formulated for diesel engines, meeting the appropriate API specifications. Optimization Tips: Consider using synthetic oil for improved protection and longer intervals. Regularly check the oil level and top it off as needed between changes.

2. Fuel Filter Replacement

The fuel filter is crucial for removing contaminants from the diesel fuel before it reaches the engine. Clogged fuel filters can restrict fuel flow, leading to poor performance and engine damage.

Best Practices: Replace the fuel filter at the recommended interval, typically every 10,000 to 20,000 miles, depending on the manufacturer's recommendations. Common Mistakes to Avoid: Don't use generic fuel filters; ensure you are using a filter specifically designed for your diesel engine. When replacing the filter, prime the fuel system to remove air bubbles and ensure proper fuel delivery.

3. Air Filter Maintenance

A clean air filter is essential for providing the engine with clean air for combustion. A dirty air filter restricts airflow, reducing power and fuel efficiency.

Best Practices: Inspect the air filter regularly and replace it when it's dirty or clogged. The frequency of replacement depends on driving conditions, but typically every 12,000 to 24,000 miles is recommended. Ensuring Each Step is Easy to Follow: Use a high-quality air filter specifically designed for your engine. Consider using a washable and reusable air filter for long-term savings and environmental benefits.

Tips Before Maintaining Your Diesel Engine

Before you start any maintenance on your diesel engine, there are a few things to keep in mind. Always consult your vehicle's owner's manual for specific maintenance recommendations and intervals. It's equally important to use the correct fluids and filters specified for your engine. Avoid using generic parts, as they may not meet the stringent requirements of diesel engines. Ignoring these tips can result in reduced engine performance, increased fuel consumption, and potentially serious engine damage.

Common Issues and Solutions Related to Diesel Engines

One of the most common issues in diesel engines is*injector problems. Dirty or clogged fuel injectors can cause poor fuel atomization, leading to reduced power, rough idling, and increased emissions. Regularly using a fuel injector cleaner specifically formulated for diesel engines can help to keep the injectors clean. In severe cases, the injectors may need to be professionally cleaned or replaced.

Another common issue is*exhaust gas recirculation (EGR) valve problems. The EGR valve recirculates a portion of the exhaust gas back into the intake manifold to reduce NOx emissions. Over time, the EGR valve can become clogged with soot and carbon deposits, causing it to malfunction. Cleaning the EGR valve can often restore its functionality.

Turbocharger issues can also plague diesel engines. The turbocharger is responsible for forcing more air into the engine, increasing power and efficiency. Turbochargers are susceptible to damage from oil starvation, foreign object debris, and excessive heat. Regular oil changes and proper maintenance can help to prevent turbocharger problems.

Finally,diesel particulate filter (DPF) problems are becoming increasingly common as diesel engines become more sophisticated. The DPF traps soot and particulate matter from the exhaust gas. Over time, the DPF can become clogged, reducing engine performance. DPF regeneration is a process that burns off the accumulated soot. However, if the DPF is not regenerated properly, it can become permanently clogged, requiring replacement.

Conclusion

Proper maintenance is essential for keeping your diesel engine running smoothly and efficiently for years to come. By following these maintenance tips and addressing common issues promptly, you can maximize the performance, longevity, and reliability of your diesel vehicle. Remember to always consult your owner's manual and seek professional assistance when needed. By implementing these practices, you can ensure your diesel car continues to deliver the power and efficiency you depend on. Don't hesitate to prioritize regular maintenance to protect your investment and enjoy the many benefits of driving a diesel-powered vehicle.